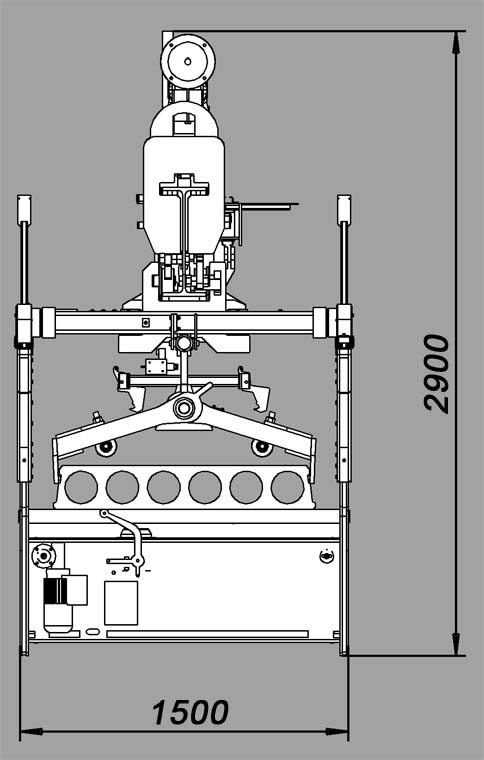

THK-drill, automatic water hole drill fitted to lifting beam

-

Technical specification:

Weight 2x800 kg -

Hydraulic specification:

Hydraulic power 2 x 1,5 kW -

Electrical specification:

Connecting power 5 kW

Power supply 3 x 16 A / 400 VAC /50 Hz + PE

Power supply and controls between THK-Collect and over head crane (4 nos, 230V AC) require a cable drum on the crane. -

Fitted onto the THK-Collect unit the THK-Drill automatically drills condensate extraction holes into the hollow slab. Afterwards the hollow slabs may be stacked in the correct unloading order. The water holes are intended to remove excess condensate from the hollow slabs to avoid moisture problems of the future buildings.

-

Once the drill has been started the automatic control takes over and finishes the drilling. The start button is located in the crane control box. Drilling positions have been preprogrammed in the control logic so that changing of the hollow slabs is simple. The selection switch is located in THK-Collect's switchboard on the top of the lifting beam.

-

After the drill has been started the following oprations take place:

1. The drill unit positions itself under the hollow slab and moves on to the correct

drilling point on the bottom surface.

2. The unit starts drilling the water holes according to chosen predetermined

program. From the program menu you may choose programs: 8=160/8 hollow slabs, 6=200/6 hollow slabs, 5=265/5 hollow slabs, 4=320/4 and other four holes hollow slabs.

3. After completion the drill returns back to base.

4. The drilling unit returns to its lower position and maneuvers back to the

beginning position.